Introduce

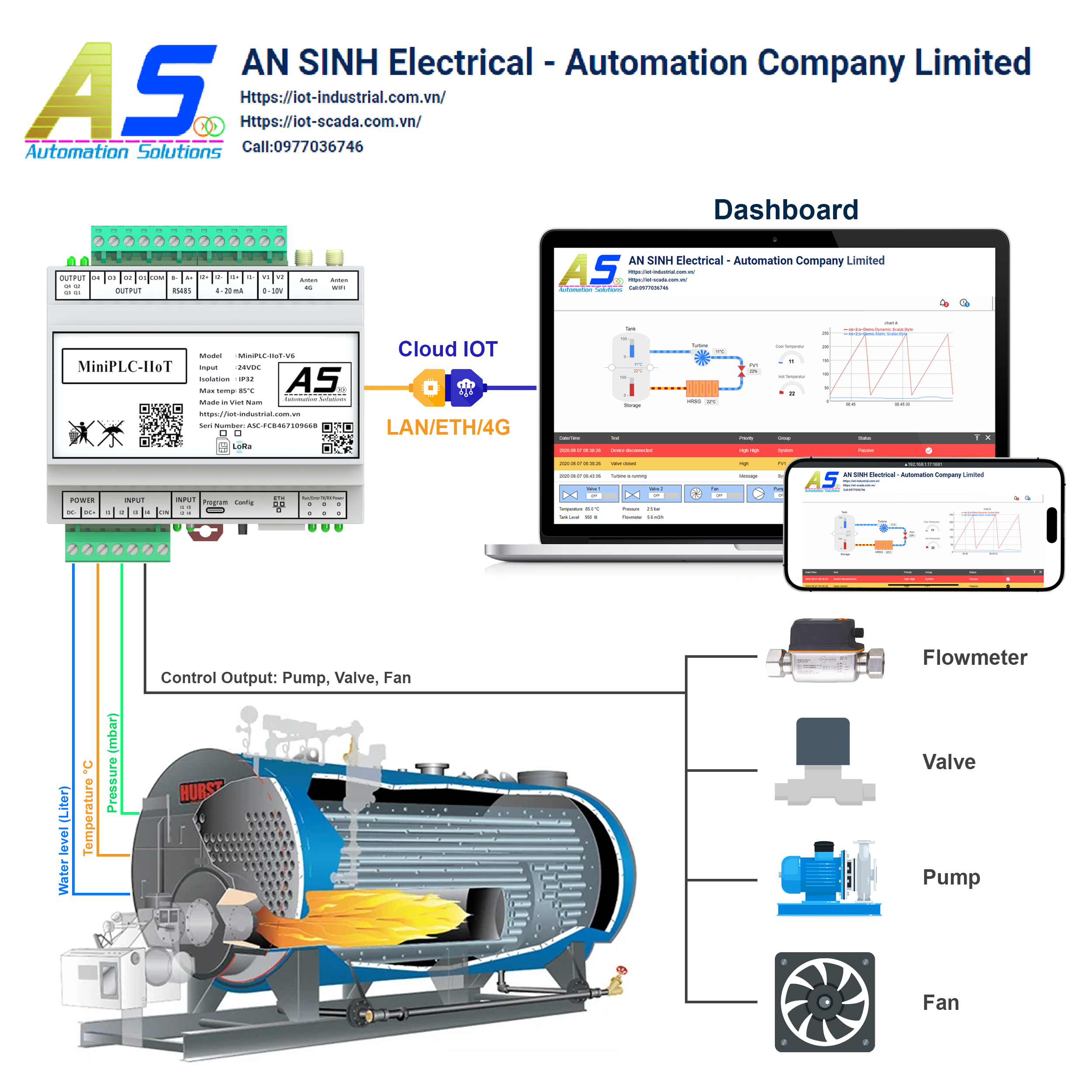

Boiler monitoring and control is extremely important in manufacturing plants. The solution uses Mini PLC combined with IoT and Dashboard to help optimize the operating process, ensure safety and save energy.

System structure

- Mini PLC: Is a Logic control device and collects data from sensors, processes and controls devices.

- Sensor: Measure parameters such as temperature, pressure, water level, flow...

- Control equipment: Valves, pumps, fans... to regulate the operation of the boiler.

- Dashboard: Intuitive interface for users to monitor and control the system remotely.

Benefit

- Visual monitoring: Dashboard displays important parameters of the boiler visually, helping operators easily monitor and detect problems.

- Remote control: Users can control devices and change operating parameters from anywhere with an internet connection.

- Warning: The system will automatically detect and alarm when there are problems such as overheating, overpressure, water loss...

- Energy optimization: Helps reduce fuel consumption and increase boiler performance.

- Increase reliability: Minimize the risk of incidents, ensuring safety for operators and equipment.

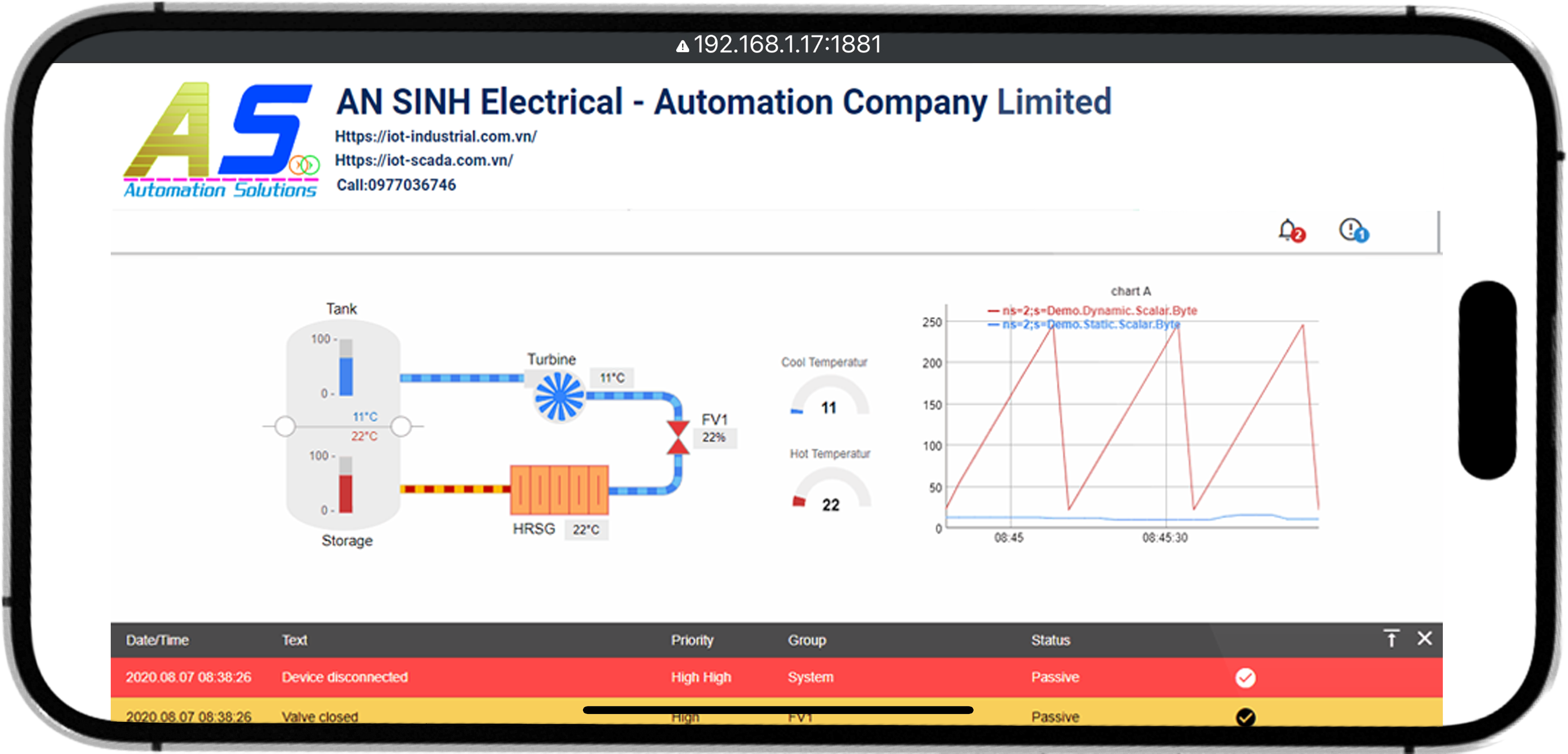

Dashboard features

- Graph display: Represents changes in parameters over time (temperature, pressure...).

- Reporting: Create detailed reports about boiler operations.

- Warning: Notify when there is a problem or parameters exceed allowable limits.

- Remote control: Control devices and change operating parameters.

-Data history: Store data to analyze and optimize operating processes.