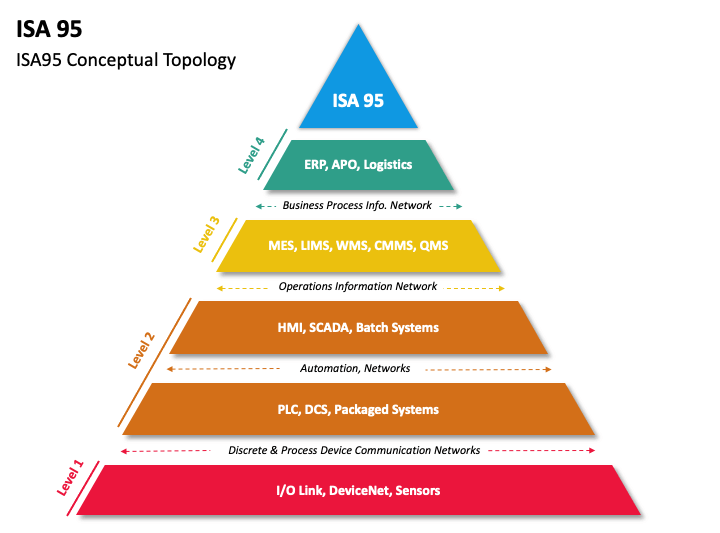

An Sinh MES includes many main structures, each of which takes on a specific role in managing and optimizing the production process:

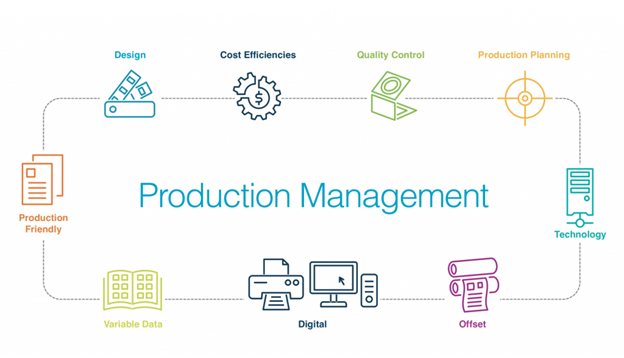

1. Production Management:

This is the main component of An Sinh MES, responsible for managing and coordinating the production process from receiving production orders until completion. Functions include production scheduling, resource allocation, and production progress tracking. The system provides real-time information about production performance, helping managers quickly detect and handle arising problems.

- Production Scheduling: Optimize production schedules based on requirements, resources, and required time.

- Production Tracking: Provides real-time data on the status of each production order.

- Order Management: Manage and monitor from ordering to completed production.

- Work Dispatching: Assigning work to machines and employees based on production plans.

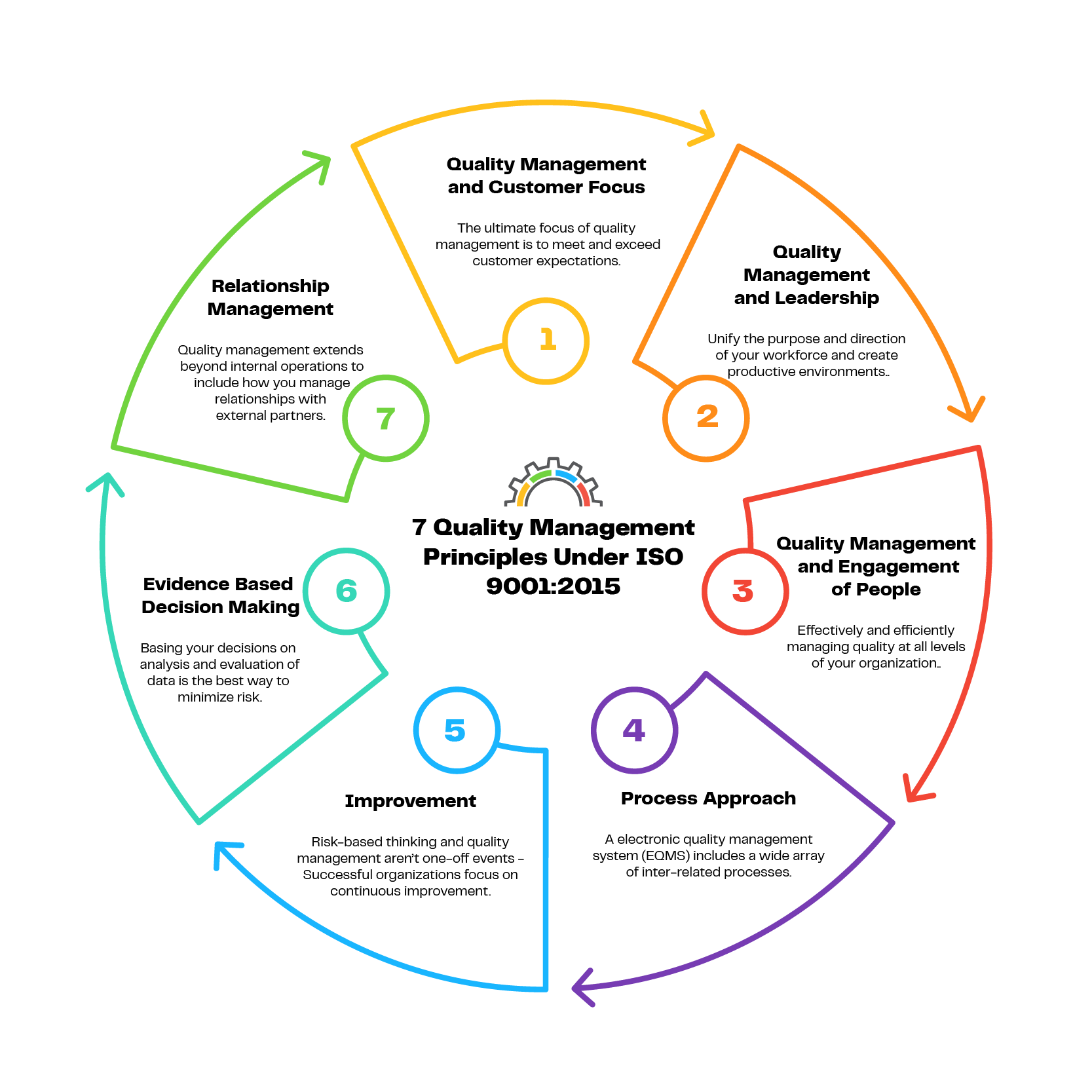

2. Quality Management:

This structure focuses on quality control throughout the manufacturing process. It includes collecting and analyzing quality data, performing testing and evaluating products at different stages. An Sinh MES helps ensure that the final product meets established quality standards.

- Quality Inspection: Carry out inspection at production stages to ensure products meet standards.

- Data Collection & Analysis: Record and analyze data to detect quality errors early.

- Non-conformance Management: Identify, record, and manage non-standard products.

- Implement corrective and preventive actions (CAPA): Implement corrective measures when detecting errors and propose prevention for the future.

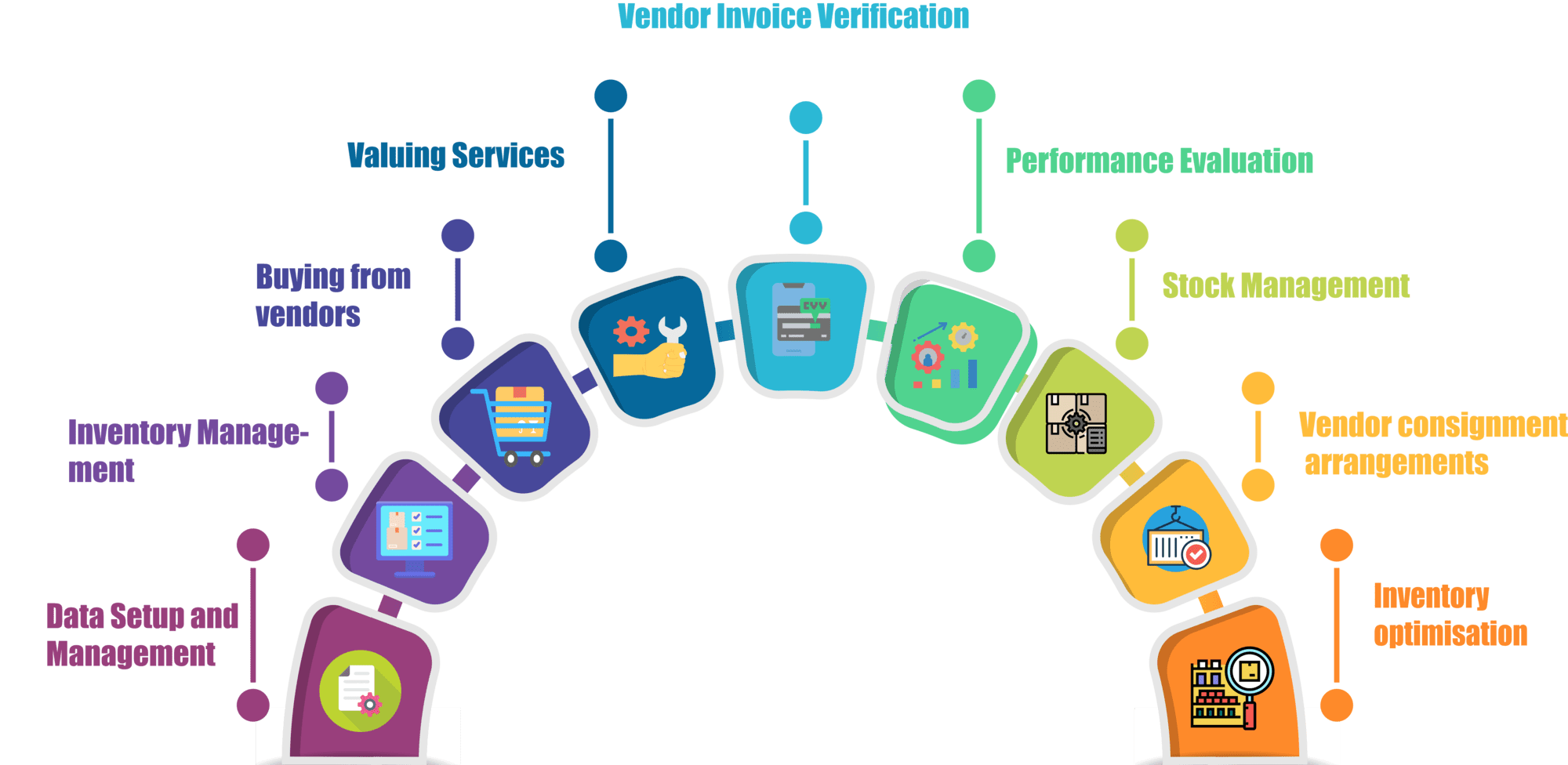

3. Material Management:

This component ensures that necessary raw materials and supplies are always available and used effectively during the production process. It tracks inventory, manages inbound and outbound material flow, and optimizes resource usage to minimize waste.

- Inventory Management: Monitor and manage inventory of raw materials, semi-finished products, and finished products.

- Material Tracking: Monitor material flow from input to finished product.

- Optimize material use (Material Optimization): Use materials optimally to minimize waste.

- Supplier Management: Manage relationships with raw material suppliers, ensure quality and delivery time.

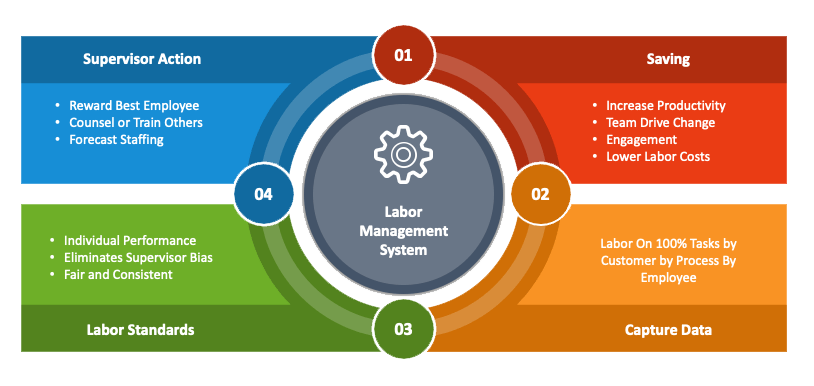

4. Human resource management (Labor Management):

This structure focuses on managing and optimizing workforce resources. It tracks employee attendance, performance, and ensures that manpower is allocated effectively according to production needs. An Sinh MES also supports training and skill development of employees.

- Attendance Tracking: Manage working hours and track employee presence.

- Performance Management: Evaluate and monitor employee performance based on production targets.

- Labor Planning & Allocation: Allocate human resources in accordance with current production requirements.

- Training and Development: Manage training and skill development programs for employees.

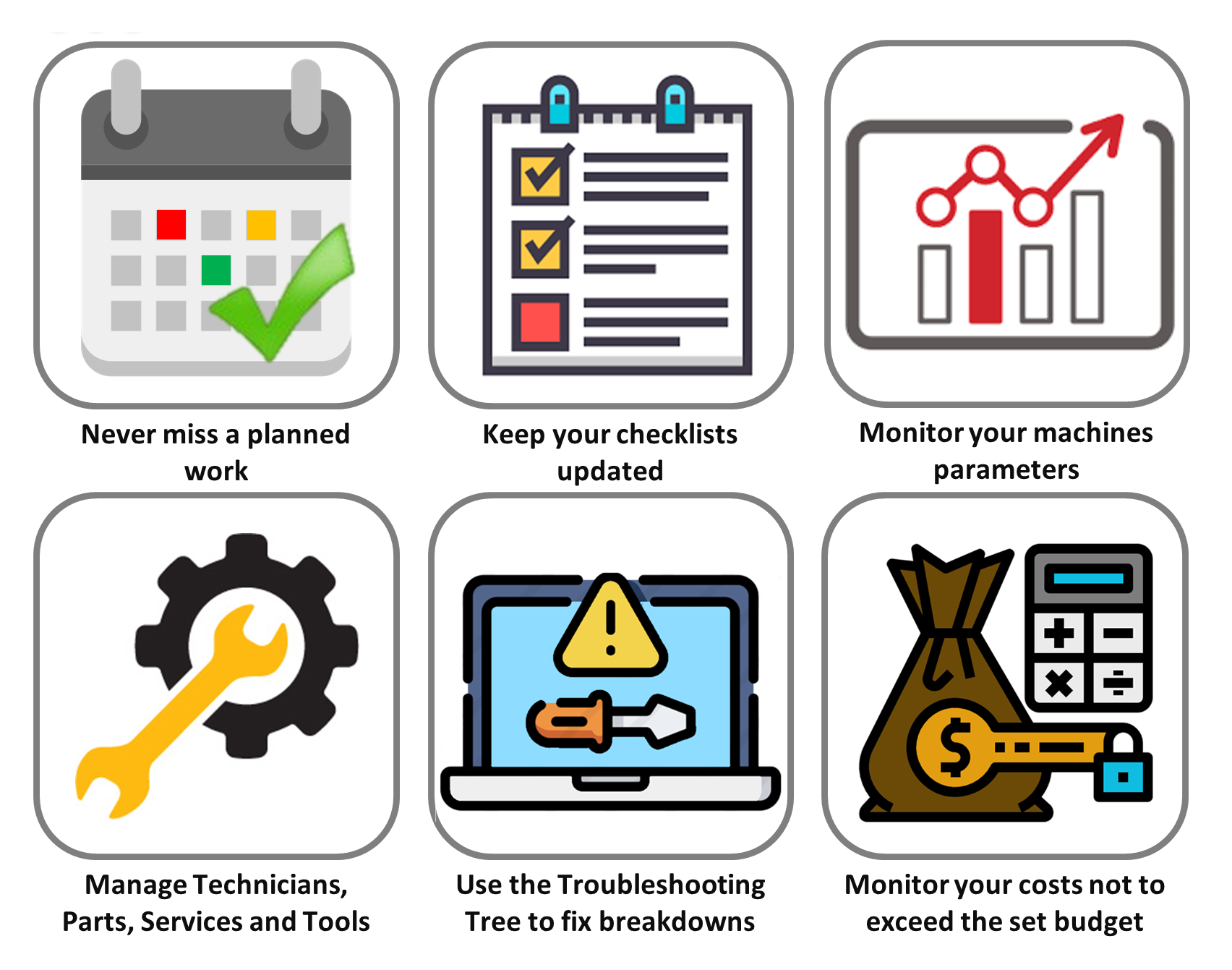

5. Maintenance Management:

This system monitors and manages equipment and machinery maintenance activities in the factory. An Sinh MES helps plan and track routine maintenance activities, minimizing unwanted downtime and ensuring equipment always operates at optimal performance.

- Preventive Maintenance: Schedule periodic equipment maintenance to minimize downtime.

- Condition-Based Maintenance: Monitor equipment condition and plan maintenance when necessary.

- Repair Management: Record and manage equipment repair activities when problems occur.

- Monitor and analyze equipment performance (Equipment Performance Tracking & Analysis): Evaluate the performance and condition of the equipment over time.

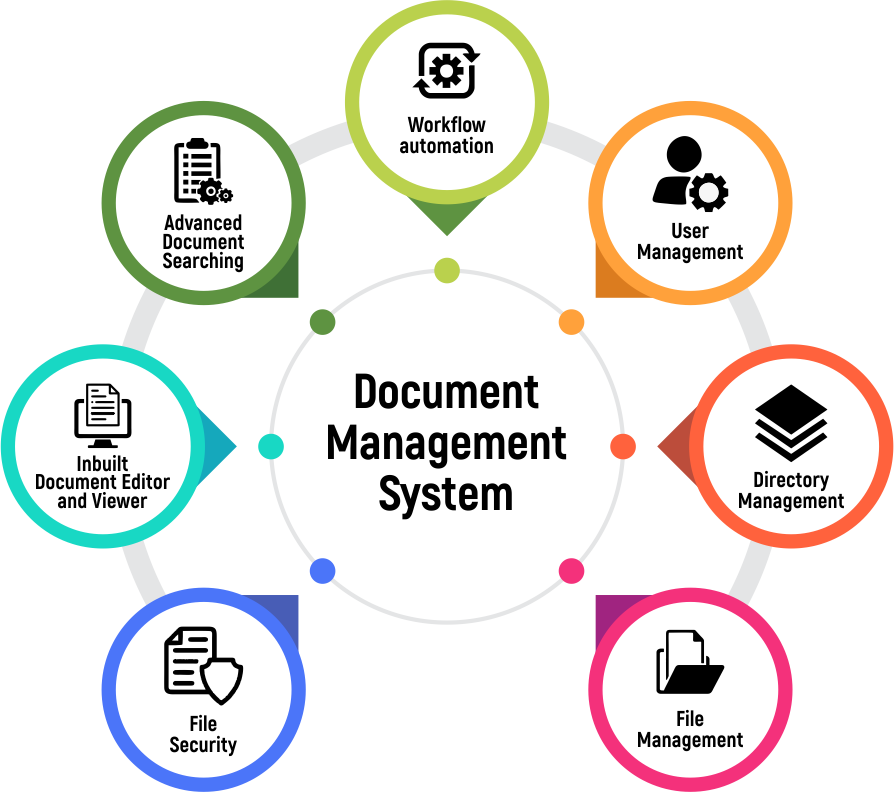

6. Document & Process Management:

This component manages documents related to the manufacturing process, including work instructions, standard operating procedures (SOPs), and other technical documents. An Sinh MES ensures that all these documents are always up to date and easily accessible when needed.

- Technical Document Management: Store and manage technical documents such as drawings, SOPs, and operating instructions.

- Version Control: Ensure all documents are up to date and track different versions.

- Process Management: Manage and monitor the production process, ensuring compliance with standards and regulations.

- Compliance Support: Ensures that all manufacturing activities comply with legal regulations and industry standards.