OEE Software of An Sinh Company: Optimal Solution in Production Monitoring

In the modern industrial context, optimizing production performance is one of the decisive factors for business success. An Sinh Company's OEE (Overall Equipment Effectiveness) software was born to meet this need, helping businesses monitor and optimize the production process in the production management system (MES - Manufacturing Execution System). Below are the outstanding features and advantages of this OEE software.

1. Comprehensive production efficiency monitoring features

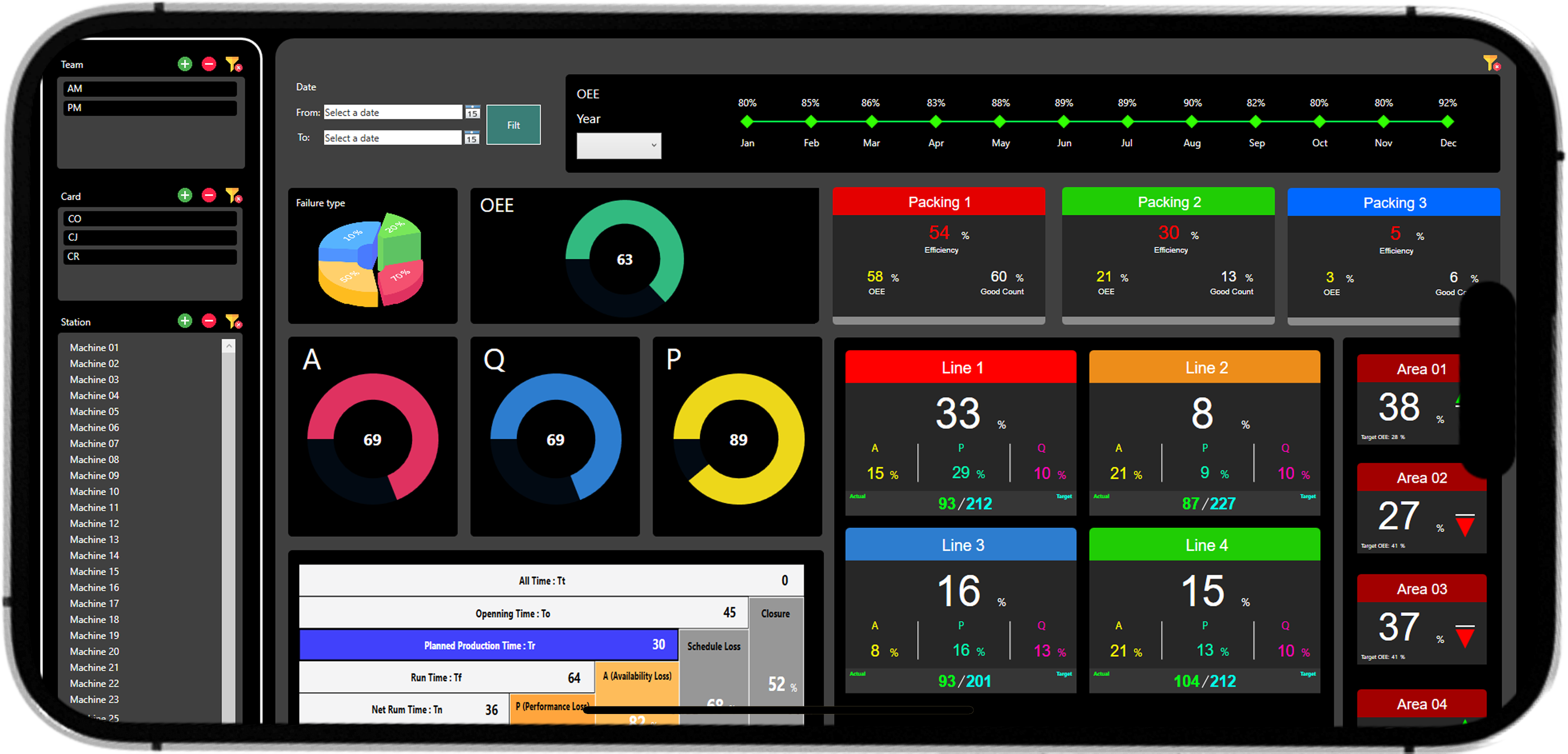

An Sinh Company's OEE software provides powerful tools to monitor the efficiency of production equipment usage. Data is collected in real time from machines and equipment in the production line, helping businesses easily track key indicators such as:

- Availability: Measures the actual uptime of the device compared to the expected uptime.

- Performance: Compare actual production speed with theoretical production speed.

- Quality: Evaluate the ratio of standard products compared to the total number of products produced.

2. Detailed analysis and reporting

OEE software not only collects data but also provides powerful analysis tools. Detailed reports help businesses understand the causes of problems occurring during the production process, thereby providing effective solutions. These analytics features include:

- Real-time reporting: Businesses can view reports as soon as the production process takes place, helping to promptly respond to arising problems.

- Root Cause Analysis: Helps identify the main causes of waste and problems in production.

- Compare data over time: Allows businesses to compare production efficiency over different periods, helping to evaluate improvements that have been made.

3. Optimize production process

One of the outstanding advantages of OEE software is the ability to optimize production processes. Based on analytical data, the software recommends process improvement measures, helping businesses:

- Minimize machine downtime: Increase equipment availability through preventive maintenance measures.

- Increase production efficiency: Adjust production speed to achieve optimal performance while still ensuring product quality.

- Improve product quality: Reduce the rate of defective products by optimizing quality control processes.

4. Easy integration with MES system

An Sinh's OEE software is designed to integrate easily with businesses' existing MES systems. This helps ensure continuity in the production process, while allowing businesses to make the most of available data in the system to improve OEE.

- Data integration: Synchronize data from MES systems and OEE software to create a comprehensive picture of the production process.

- Compatible with many types of equipment: The software is capable of connecting to many different types of machines and equipment in the production line, helping to ensure the flexibility and expansion of the system.

5. Strategic benefits for businesses

Applying OEE software from An Sinh Company not only brings immediate benefits in monitoring and optimizing production but also creates long-term strategic values for businesses:

- Improve competitiveness: Enterprises can produce more quality products in a shorter time, thereby enhancing competitiveness in the market.

- Cost savings: Minimizing resource waste and optimizing equipment usage helps businesses save operating costs.

- Decision support: Provide accurate and timely data, helping management make strategic decisions based on actual information.

6. Convenient Remote Control Interface

An Sinh Company's OEE software is designed with a modern and friendly user interface, allowing businesses to easily monitor and control the system remotely. This is an important factor to help manage production more effectively, especially in modern industrial environments.

- Intuitive interface: The interface is designed with charts, data tables and visual reports, helping users easily track important OEE indicators without having to have in-depth technology knowledge. .

- Remote access: The software supports remote access via Internet-connected devices such as computers, tablets, or mobile phones. This helps managers monitor and adjust production activities from anywhere, at any time.

- Instant notifications: The system provides instant notifications when detecting problems or when there are any fluctuations in the production process, helping managers promptly make decisions to minimize risks and reduce risks. damage.

- Flexible adjustments: The remote control interface allows users to make necessary adjustments to the production process immediately, without being physically present at the factory. This enhances flexibility

- High security: The system is equipped with advanced security measures, ensuring that important business data and information are protected from external threats, and only authorized users New powers can access important functions.