In refrigeration systems or especially cold storage, incidents in the cooling system can cause huge losses for businesses, even damaging the food stored in warehouses. cold.

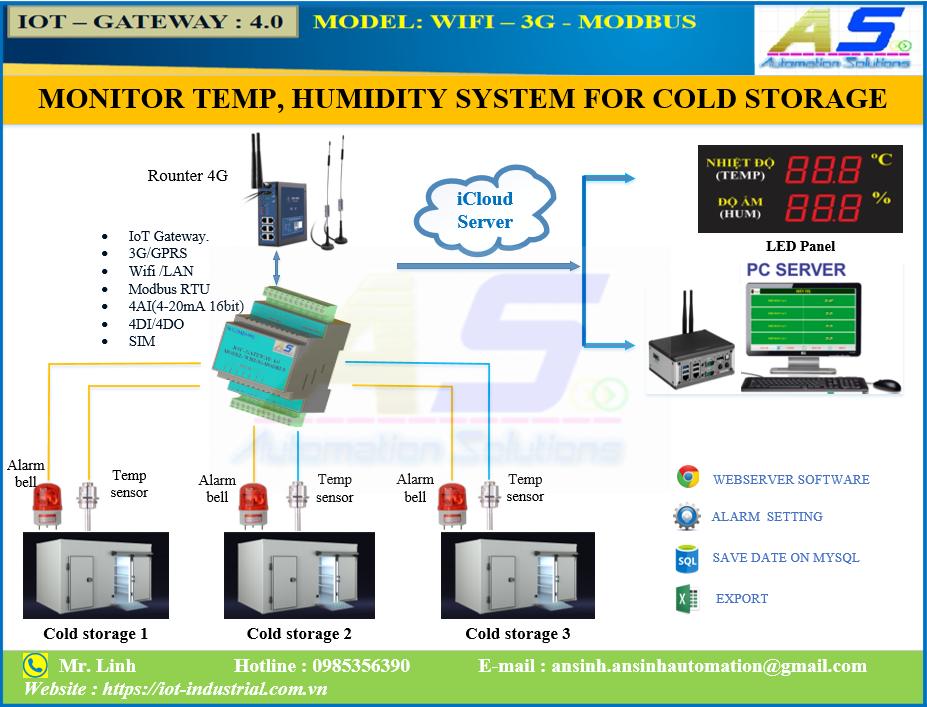

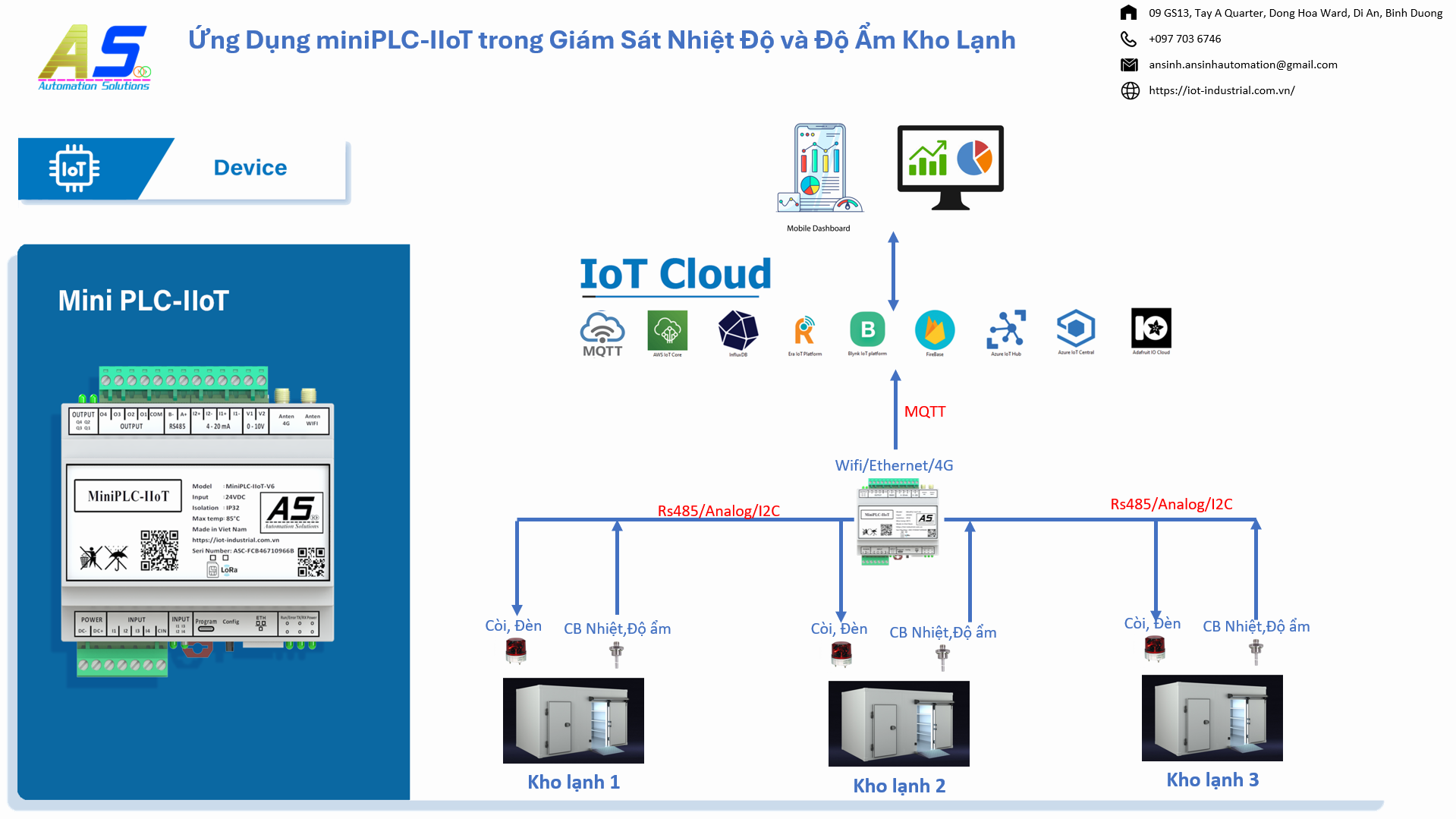

A reliable monitoring and management system can monitor most common incidents such as power outages, door openings, temperature drops, cooling system failures, etc., these incidents can be alerted as quickly as possible. and send it to the supervisor to be able to solve problems as quickly as possible via text message or email, thereby reducing loss and repair costs. The following figure depicts a solution to monitor the cold storage and cooling system.