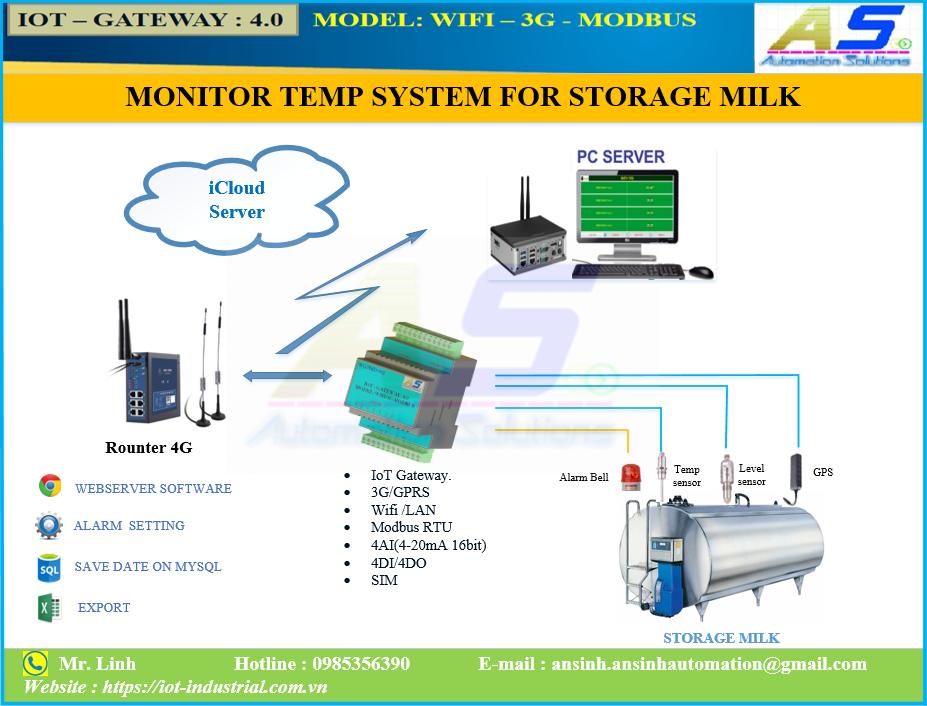

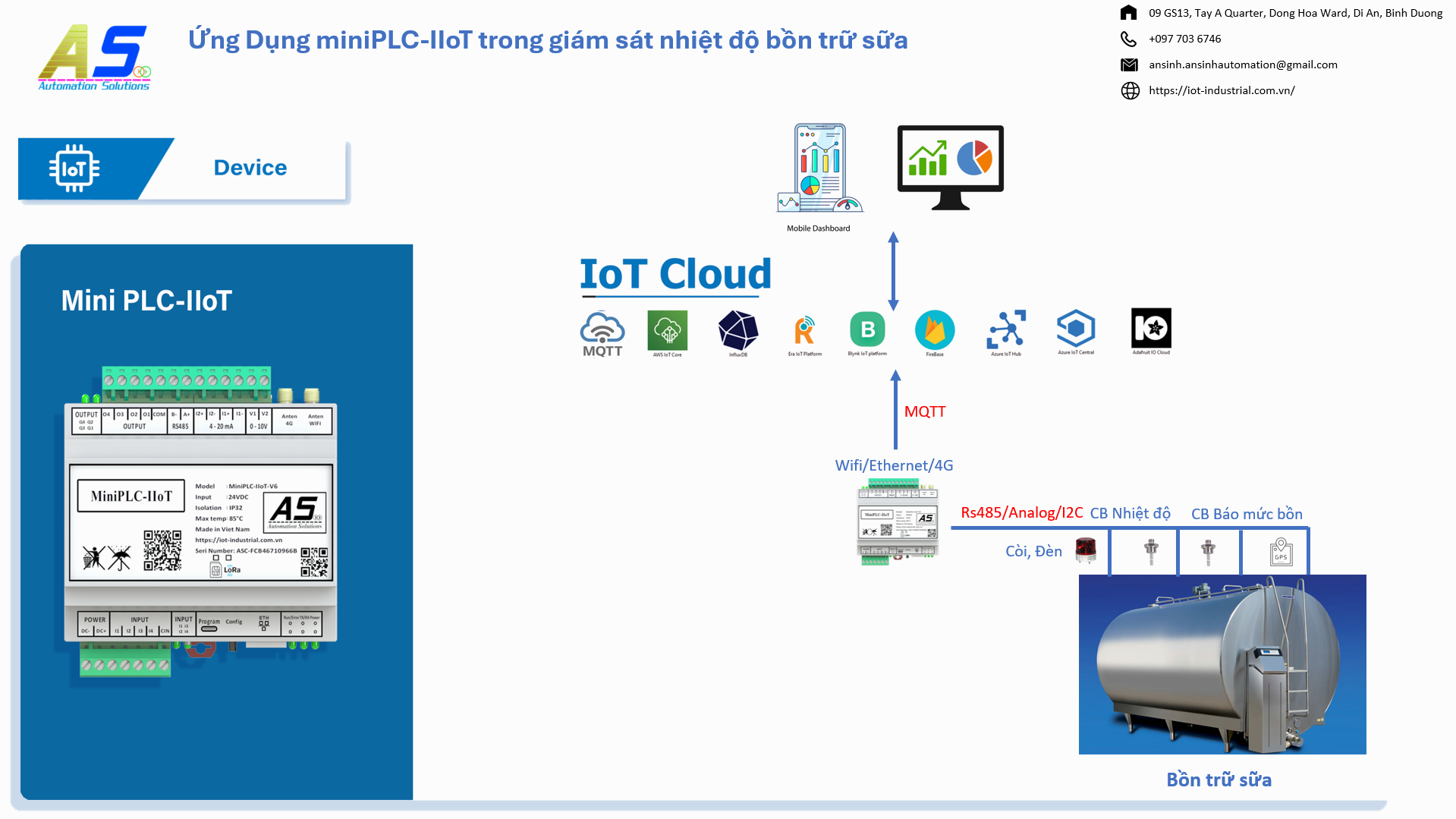

With the need to monitor and monitor the condition of the milk storage tank is always in the perfect state of storage. An Sinh Electrical - Automation Co., Ltd has proposed a solution to remotely monitor milk storage tanks.

To meet the above needs, the Company has researched and designed a temperature monitoring system to ensure the status of milk storage tanks 24/24.

In addition, the system is equipped with on-site warning devices such as horn lights, monitoring, remote alerts such as GPS, SMS, Email to customers when incidents increase or decrease the temperature of the system. milk storage tanks beyond the allowed limit.